Our Services

PRODUCTION

We aim to provide a complete equipment production process, starting from conceptualization, drafting, and development of supporting documentation and models, through to production, assembly, and testing. We have been delivering high-quality products to our customers since the early 2000s in both offshore and subsea applications. Many of our designs for various tooling have been produced in our workshops and used by companies worldwide.

We have a large production capacity for welded or machined structures, along with a full setup for anti-corrosion protection. This setup includes PTFE coating and a phosphating process we have developed in-house.

For machining purposes, we have various setups of CNC-operated and manually-operated machinery, which allow us to fabricate large-scale or smaller production pieces.

For welding and repair work, we utilize advanced technologies, including the Fronius Multi Welding System (TIG, MIG, MAG, CMT, Hardbanding, and Plasma Gauging), Fronius Endless Torch Rotation with patented Speedclad 2.0 TIG welding, Fronius robotic MIG/MAG welding with a three-axis positioner, Miller submerged arc welding, CNC plasma and oxy cutting, and post-welding heat treatment.

Our in-house quality control personnel monitors the production processes to ensure the output meets demand.

The production process is completed with a Factory Acceptance Test (FAT), during which we provide various testing setups to simulate real-life conditions in a controlled environment, according to the client’s or third-party verification vendor’s specifications.

Our production department covers:

Design and Engineering for Production

- Review of Technicial queries

- Preparation of technical solutions

- Design and Engineering packages

- Calculations and FEA analyses

- 3D models & visualisations

- Issuance of fabrication drawings

- Issuance of document packages for class/3rd Party approvals

- Issuance of fabrication technology

Procurement of materials and components

- Purchase of raw materials

- Purchase of equipment & components

- Purchase of consumables

- Purchase of specialised tools for fabrications

Anti-corrosion

- Standard blasting and coating

- Phosphating

- PTFE & Xylan coatings

- Metallisation

Production

- Machining of components

- Welding of parts and structures

- Fabrication of hydraulic systems

- Electrical and control system fabrication

- Dimensional and quality control

Equipment assembly

- Mechanical components assembly

- Hydraulic systems assembly

- Electrical systems assembly

Equipment commissioning and FAT

- Commissioning and FAT procedures

- Use of a testing bench

-

Witnessing of class and third-party inspection

-

Issuance of MRB documentation packages

- Issuance of certification

- Issuance of user manuals

Our product portfolio

Most of our projects are custom-made to meet our clients' specific needs.

Structural steel fabrication

We fabricate structural components engineered for optimal performance and customized to meet precise project specifications and client requirements.

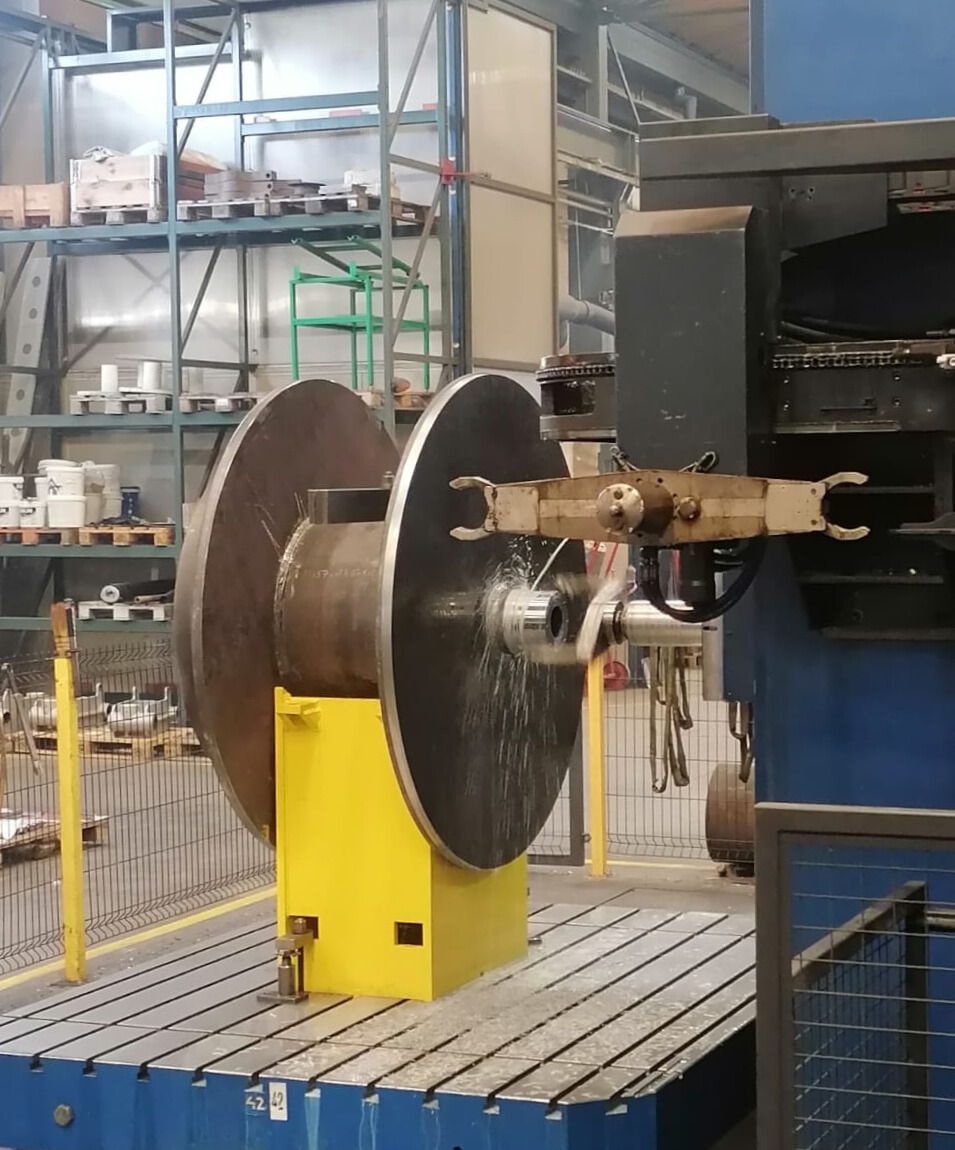

Machined parts fabrication

We fabricate machined components tailored to custom requirements, with a deep understanding of the strict compliance and precision demands involved in machining processes.

Our advanced machinery — including 3-axis milling machines, CNC lathes, and 5-axis simultaneous milling machines with turning capabilities — enables us to handle even the most complex projects with accuracy and efficiency.

Whether you need small quantities or large-scale production, we are fully equipped to deliver high-precision, high-quality results.

Deck machinery fabrication

We offer an unmatched range of deck machinery products and systems — from cost-effective winches for mooring and anchoring vessels to specialized winches and handling systems for offshore operations, tugboats, naval ships, and a wide variety of other vessel types.

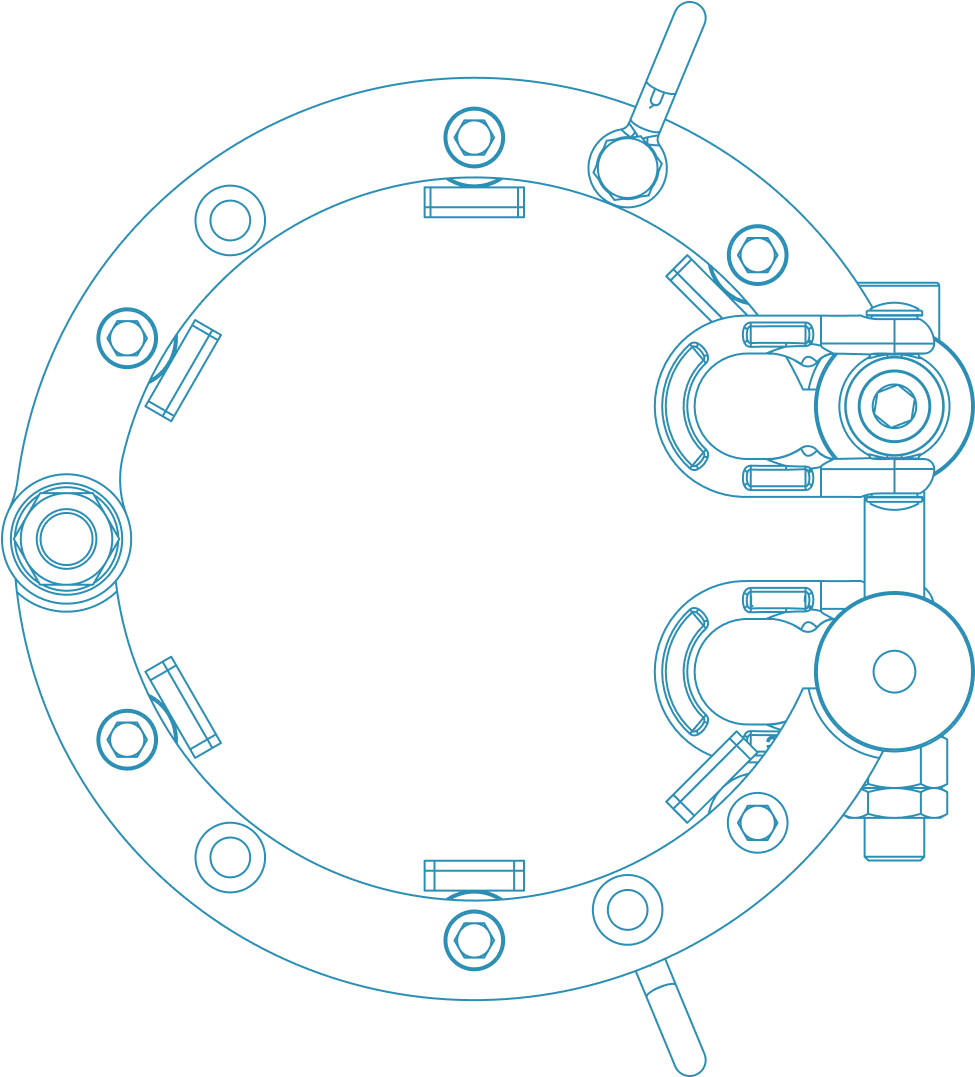

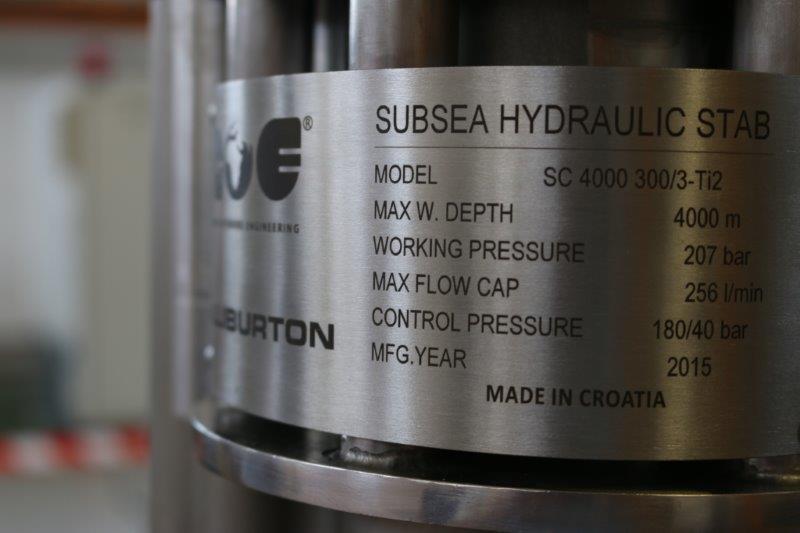

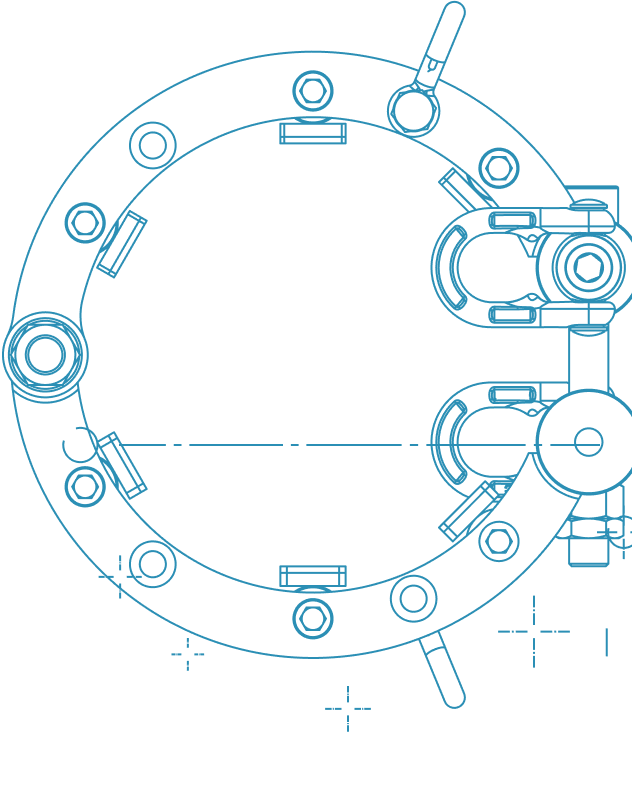

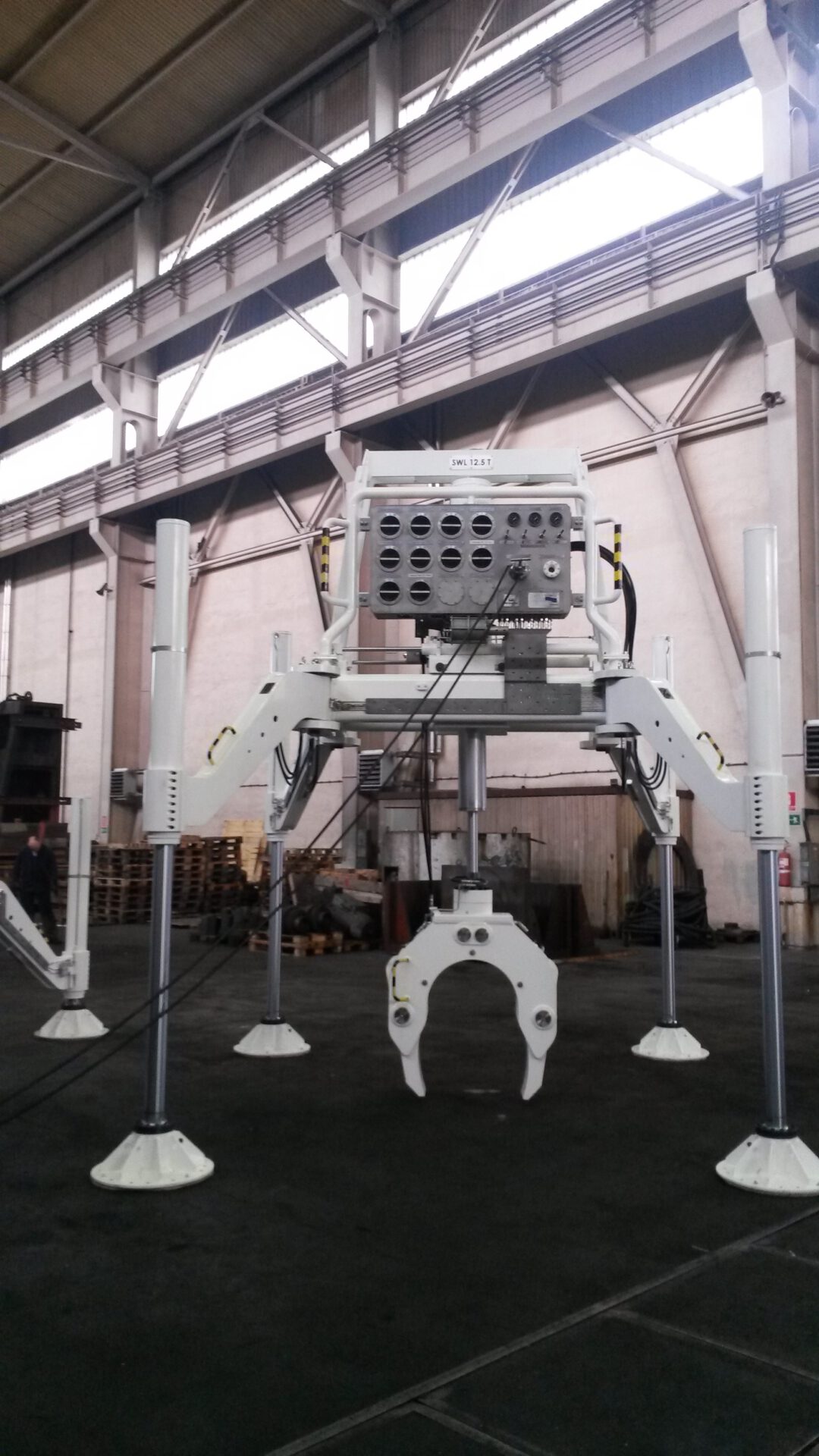

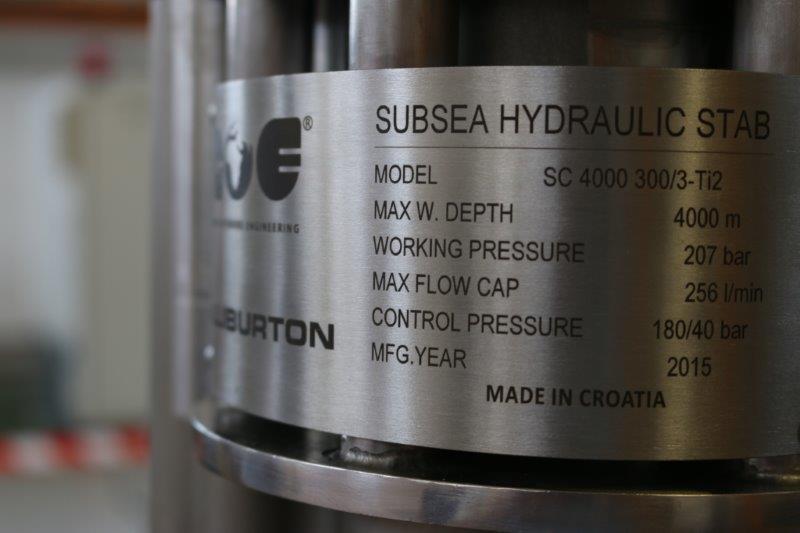

Subsea tooling packages fabrication

GOE provides advanced subsea tooling packages and innovative engineering solutions for offshore projects.

Backed by an experienced tooling team, we deliver fully integrated equipment solutions for complex subsea operations.

Our subsea products are predominantly custom-designed and fabricated to meet exact project specifications.

Featured projects

GOE has a proven track record of managing and delivering complex projects across the globe, from offshore drilling rigs to advanced engineering solutions. Explore our portfolio to see how our expertise and commitment drive success in some of the most challenging environments.

View all projects

PIPELINE LIFTING TOOL