Our Services

MAINTENANCE

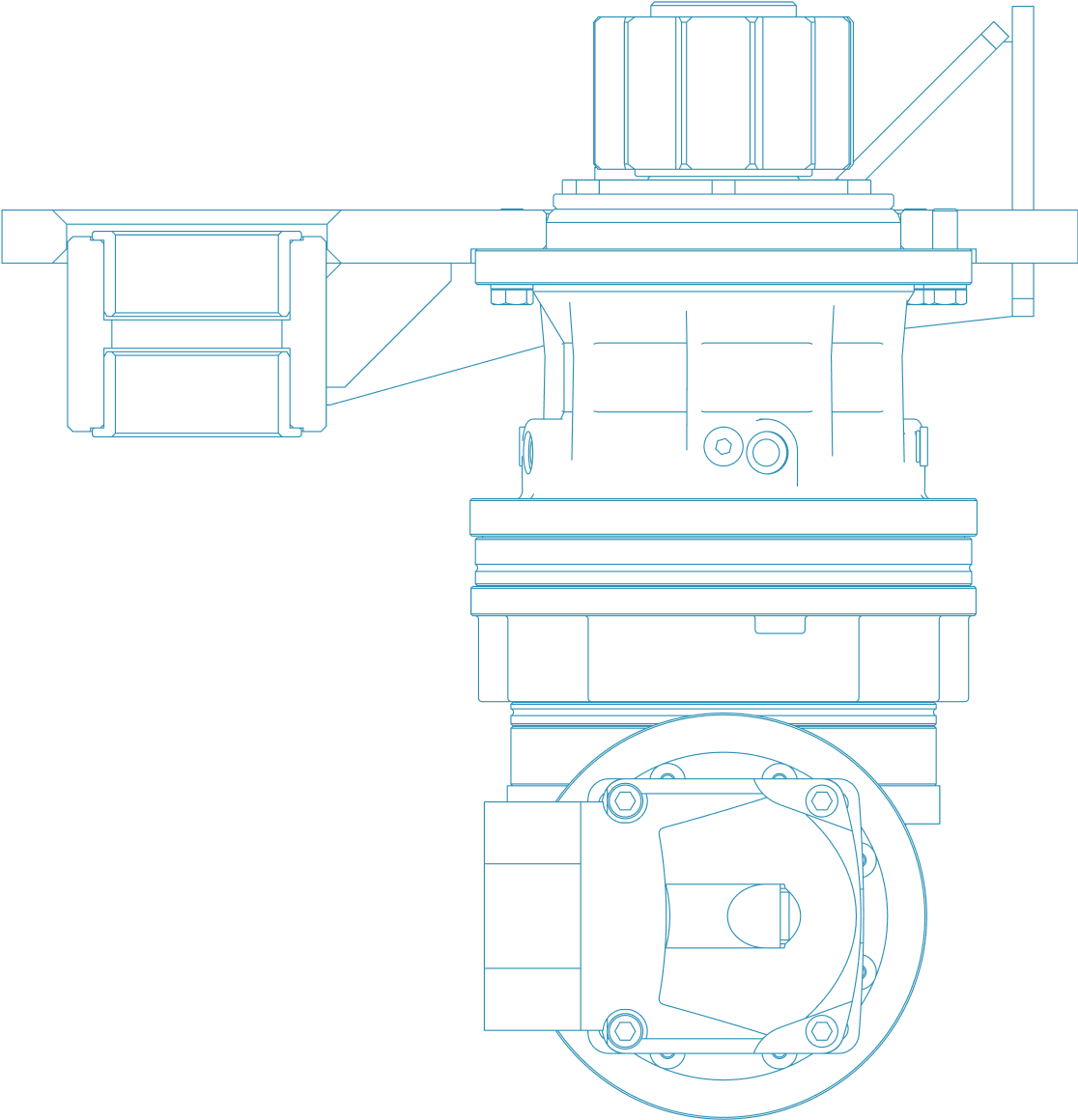

We consider maintenance and repair capability as one of our most important features. We provide a planned maintenance program based on manufacturers' recommendations, classification society guidelines, or company policies. This helps to keep plants in reliable and capable conditions.

Whether it’s preventative or unscheduled corrective maintenance, we provide the know-how and skill set to ensure uninterrupted project completion. Our experienced team, consisting of marine engineers, mechanics, hydraulics, welders, production technicians, electricians, and ETs, ensures that we can handle complex tasks on site or in the workshop, with minimum inconvenience.

We prioritize the ability to react swiftly to situations requiring unplanned corrective maintenance or repairs on machinery or equipment to get the rig running as soon as possible. Our skilled team of mechanics, electrical and engineering service teams are readily available on demand to handle any situation that might occur.

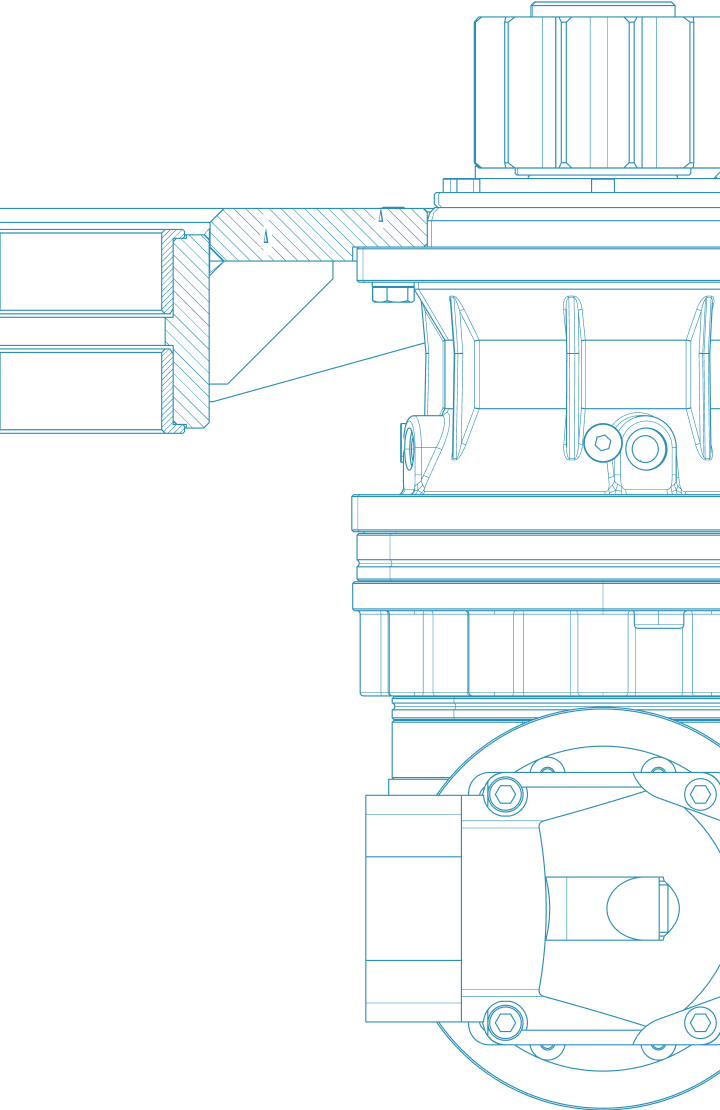

In order to ensure top quality every time, we prefer to send your equipment to our workshop for a comprehensive repair process.

Our maintenance team oversees the entire process, starting from receiving the equipment, then proceeding to disassembly and inspection, engineering disposition of repair process, necessary repairs, reassembly with new parts, and finally conducting factory acceptance testing (FAT). We are accustomed to closely collaborating with classification societies or any third-party verification company, as per client preference, during any phase of the process.

the following is included:

Rig Repairs and Maintenance Services

- Meeting customer’s needs

- Maintenance Planning & Scheduling

- Equipment dismantling, handling, servicing and reassembly

- Mechanical services

- Structural Engineering and Services

- Electrical services

- Fluid Power services

- NDT services

- Well control system services

- Custom Fabrications, supervision and Process Control

- Assembly and Testing

- Commissioning

Recertifying, including

- 5-year SPS planning and conducting

- 10-year SPS planning and conducting

- Project Planning and Scheduling

- Project Scopes, controlling resources

- Project Budget Cost Control

- Quality Inspection

- Procurement

- Work Progress Monitoring

- Mobilization Planning

- Service logistics

- Engineering support

- Planning, custom tools, fabrications

- Project management

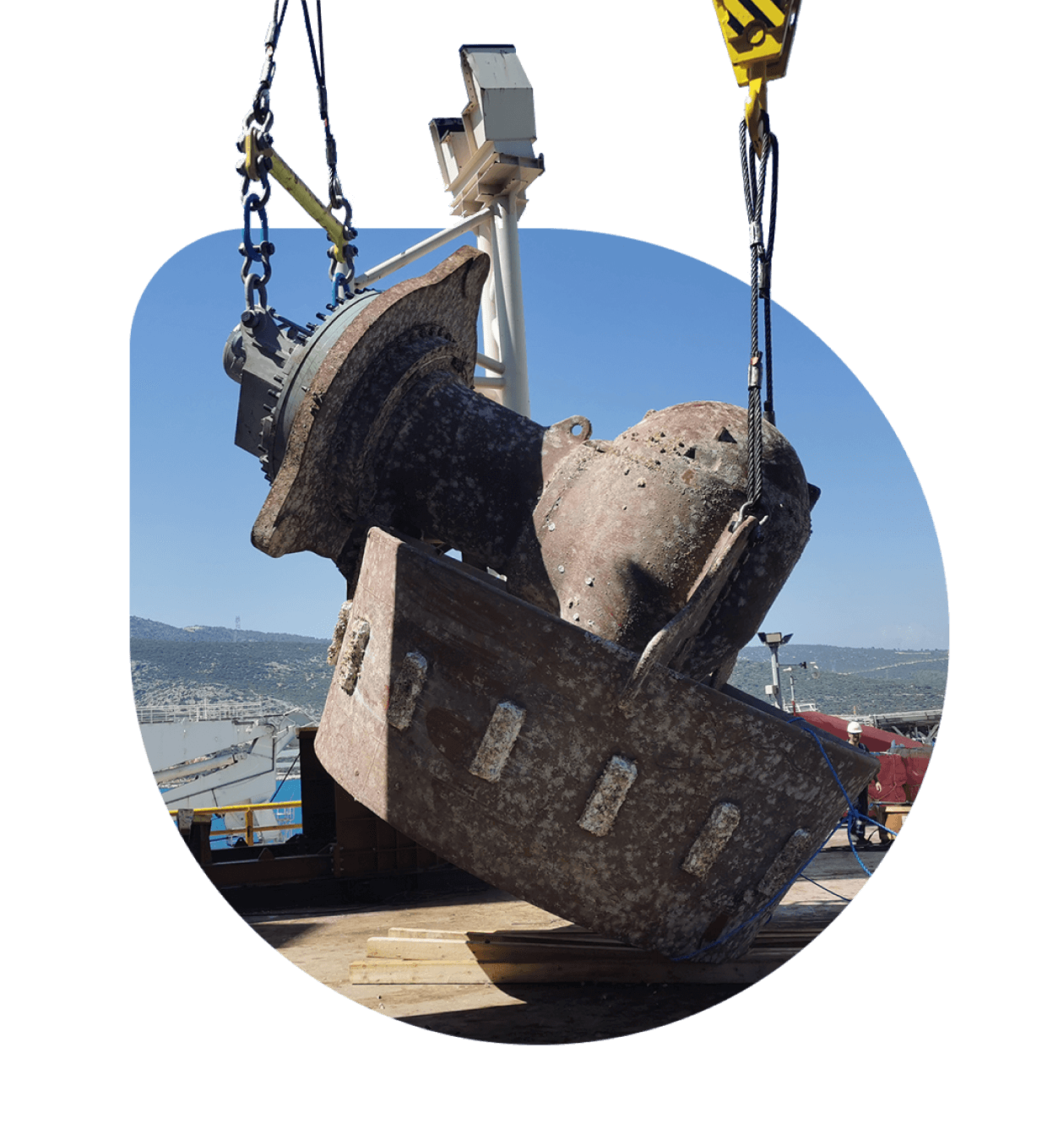

Featured projects

GOE has a proven track record of managing and delivering complex projects across the globe, from offshore drilling rigs to advanced engineering solutions. Explore our portfolio to see how our expertise and commitment drive success in some of the most challenging environments.

View all projects

Drill ship FATIH – Riser System SPS